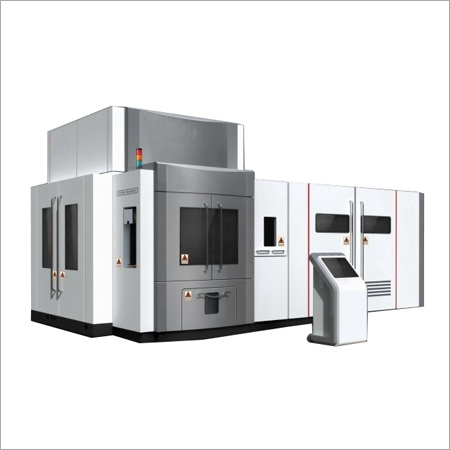

PET Stretch Blow Molding Machine

Product Details:

X

Product Description

Brief Introduction:

VD-R12 Full Automatic Rotary Blow Molding Machine is widely used for blowing plastic container including hot filling bottle, which is suitable for the product of water, tea drink, dairy, fruit juice, carbonnated beverage and pharmaceutical injection etc.

With the structure of multi-mold in one machine, can complete the actions of parison unsarambling, parison feeding,heating, stretch, blowing, cooling and bottle conveying etc full automatically. The main component on the machine are of international brands. The machine have the advantage of high level automation, reliable and stable operation, low power consumption.

Performance and Advantage:

1. High productivity: 1700pcs each cavity per hour;

2. Hopper type bottle cabinet;

3. Base taking, base feeding, bottle taking and bottle arranging are automatically completed with manipulator for avoiding middle pollution;

4. Fully closed performance to assure the bottle without pollution;

5. Complete heating system;

6. Electronic test system can accurately and automatically remove defective bottles;

7. Stable revolution and rotation, adjustable speed;

8. Low energy consumption, the heating temperature for different sections of the bottle pipe is adjustable according to actual situation;

9. Infrared ray lamp in the oven is installed with air cooling system, which can prolong the service life of infrared ray lamp and improve the efficiency of heating oven;

10. After heating, the system can automatically test the temperature of bottle with infrared ray, automatically adjust the temperature for assuring even heating and dropping the rate of polluted bottle.

Specification:

VD-R12 | Item | Data |

Specification of Bottle | Max. Capacity | 2L |

Max. Body Diameter | 120mm | |

Max. Height of Bottle | 320mm | |

Max. Diameter of Bottle Mouth | 38mm | |

Max. Preform Height | 145mm | |

Mould | Mould Cavity | 12Cavities |

Output | Nominal output for 0.5 L; 16.5gr bottle | 19,200pcs/h(cold filling) |

15,600pcs/h(hot filling) | ||

Nominal output for 2.0 L; 56gr bottle | 15,000pcs/h | |

Rate of finished product | ≥99.7% | |

Cooling System | Water inlet temperature | 10℃ |

Water inlet pressure | 5-6bar | |

Flow Rate | 180L/min | |

Cooling Capacity | 10P | |

Air Source | High pressure | 3.5~4.0Mpa |

Blowing air flux | 12~30m³/min | |

Low pressure | 0.8~1.0Mpa | |

Blowing air flux | 3.5~7.0m³/min | |

Filtering grade | 0.01micron | |

Humidity | Dehumidified | |

Dimension of Machine | L × W" H (Blowing) | 2350"3310"3150mm |

Weight (Blowing) | 9,000KGS | |

L × W × H (Oven) | 3870" 1250" 2200mm | |

Weight (Oven) | 2,000KGS | |

Motor Power | Total Power | 198kW |

Main Motor | 4kW | |

Really Power use | 35~70kW |

|

|

|

|

JIANGSU VICTOR MACHINERY CO LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |