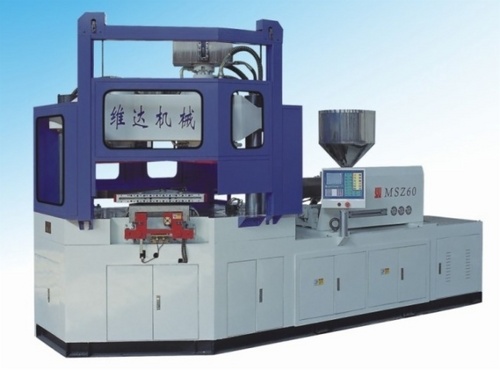

MSZ60 Injection Blow Molding Machine

Product Details:

Product Description

Mould Cavitation:

| Approx.Volume (ml) | Max.body diameter (mm) | Min.neck diameter (mm) | Max.Height (mm) | Min.Weight (gram) | Center Distance (mm) | Max.Cavitation (cav) |

| 10 | 22 | 8 | 60 | 3 | 35 | 18 |

| 30 | 30 | 8 | 75 | 4 | 40 | 14 |

| 75 | 40 | 13 | 100 | 9 | 65 | 9 |

| 120 | 50 | 18 | 120 | 15 | 80 | 8 |

| 250 | 65 | 22 | 140 | 25 | 100 | 5 |

Main Technical paramters:

| Injection system | Unit | MSZ60 |

| Screw Diameter | mm | 50 |

| Screw L/D |

| 20.6-23:1 |

| Injection weight(HDPE) | g | 280 |

| Max.screw speed | rpm | 10-235 |

| Heating capacity | KW | 10.8 |

| Clamping&blowing system |

|

|

| Clamping force of injection | KN | 600 |

| Clamping force of blowing | KN | 89 |

| Max.Platen size(L×W) | mm | 740×390 |

| Min.Mold thickness(H) | mm | 280 |

| Heating capacity of mould | KW | 6 |

| Stripping system |

|

|

| Stripping stroke | mm | 200 |

| Dry cycle | sec | 6 |

| Driving system |

|

|

| Motor power | KW | 30 |

| Hydraulic pressure | Mpa | 14 |

| Product range |

|

|

| Suitable bottle range | ml | 5-450 |

| Max.bottle height | mm | ≦200 |

| Max.Dia.of bottle | mm | ≦60 |

Processing Principle:

*Max.uniformity of bottle weight,thickness and volume

*High speed production with multi cavities available on different bottle size

*Suitable material:PE,PP,PS,SAN,PETG,EVA...etc for various bottles

*Different method as option,big space for ease mould changing

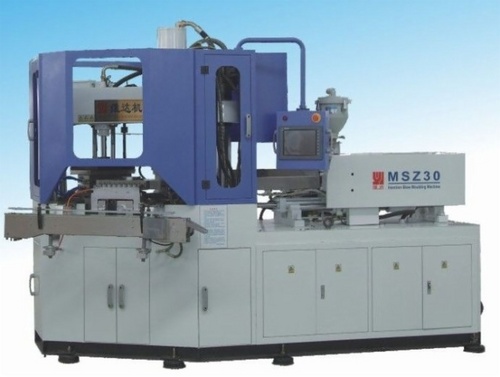

Other Products in 'Injection Blow Molding Machine' category

|

|

|

|

JIANGSU VICTOR MACHINERY CO LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |